METAL

Division

METAL

Division

Division

The largest manufacturing division

The main goal is to provide comprehensive services to customers expecting high-quality metal products, whether as individual parts or as complex functional products.

Performance Summary 2024

Total number of units produced

0

Total number of items produced

0

Total number of customer audits

0

Average audit score (%)

0

TESLA Battery Rack Cabinets

- Dimension (W x H x D): 900 x 2100 x 800 mm

- Construction: welded frame / assembled cladding

- Colour: glossy, two-component - zinc primer

Control Cabinets

- Dimension (W x H x D): 1200 x 1800 x 600 mm

- Construction: welded frame / assembled cladding

- Colour / Finish: glossy with a fine textured surface

Stainless Steel Control Cabinets

Subway applications

- Dimension (W x H x D): 800 x 1280 x 800 mm

- Construction: welded frame / assembled cladding

- Colour / Finish: glossy with a fine textured surface

- Product finish: anodized stainless steel for corrosion protection

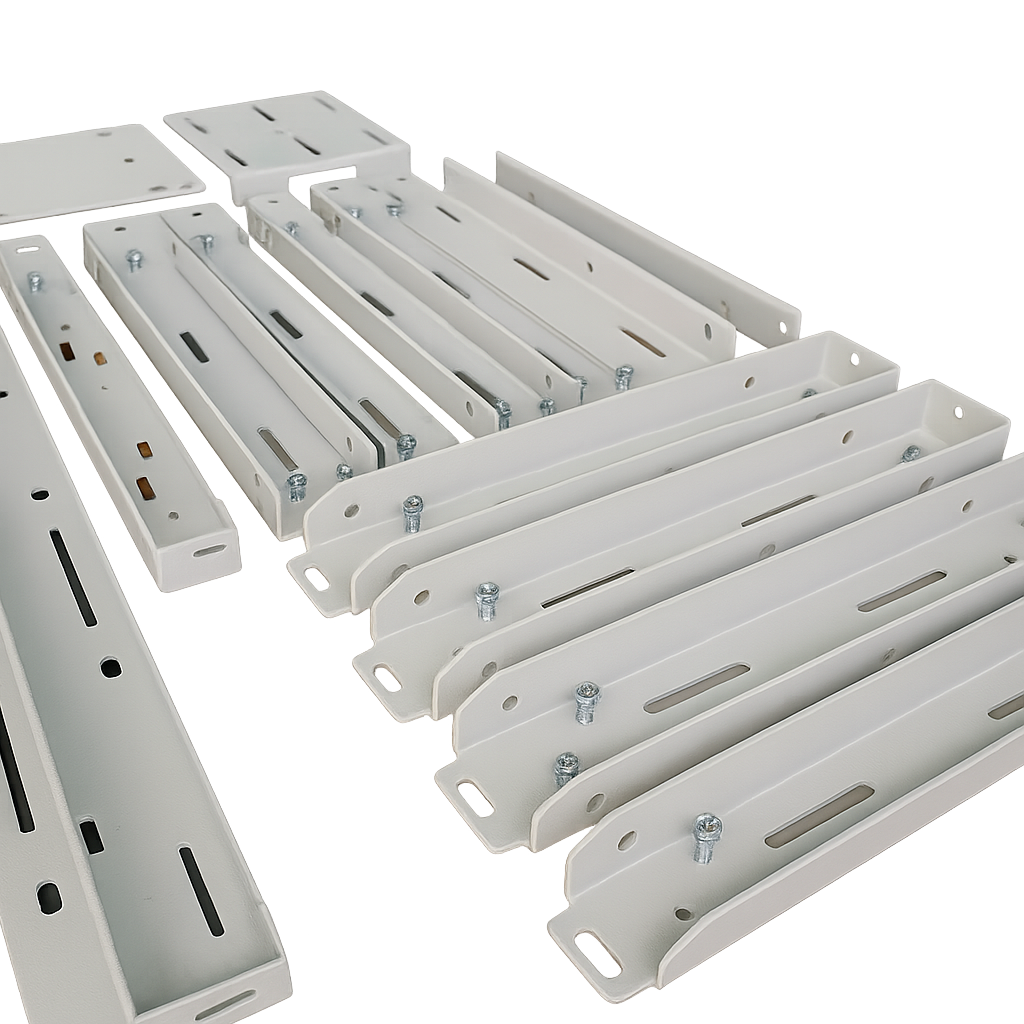

Switchgear Racks

- Dimension (W x H x D): 1250 x 1800 x 800 mm

- Construction: welded frame / riveted partitions

- Colour / Finish: two-component coating zinc primer / textured finish

- Product finish: shot-blasted surface, corrosion protection of welds

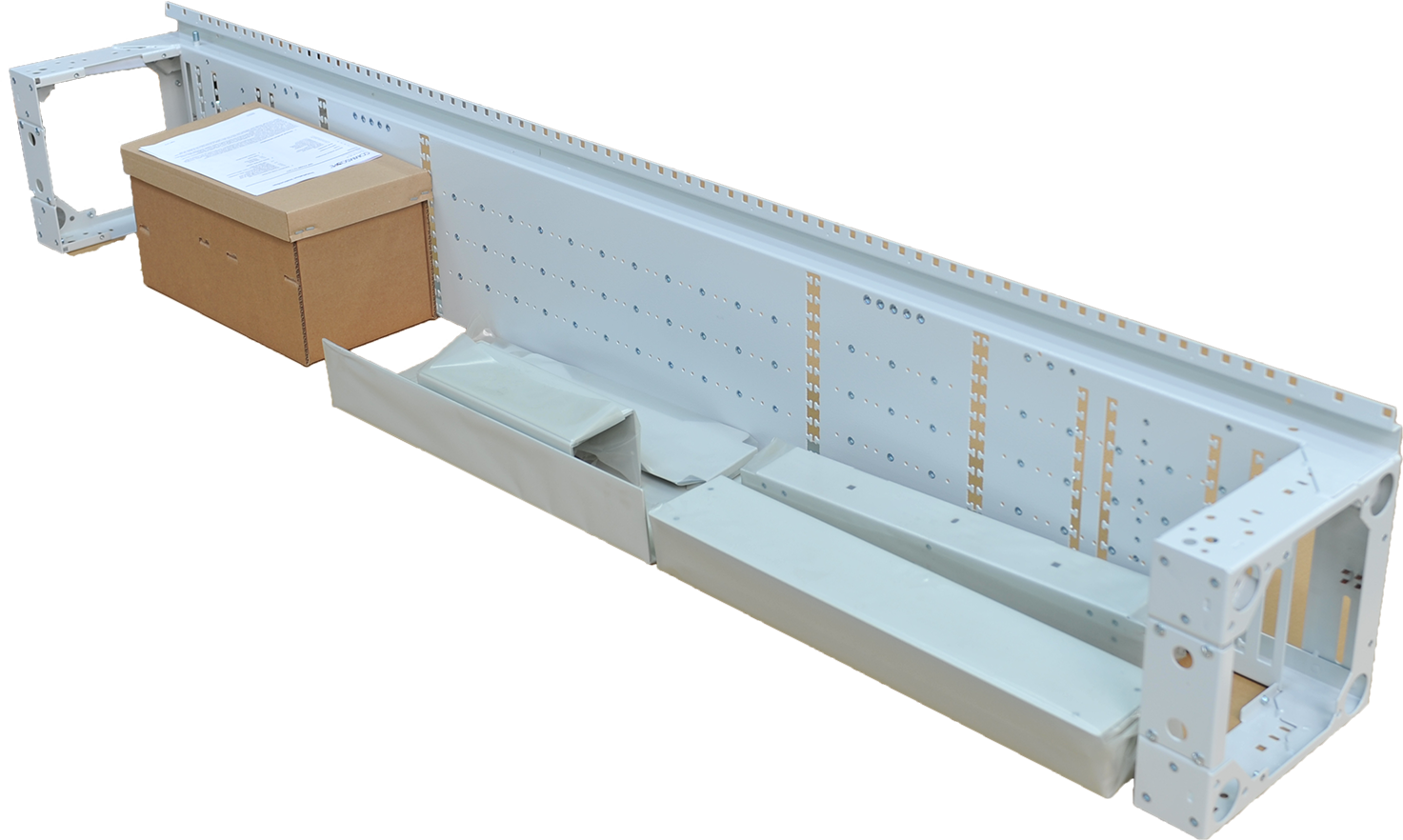

Telecom Racks

Part of a data center’s assembled / mounted system

- Dimension (W x H x D): 2200 x 200 x 350 mm

- Construction: welded frame / riveted partitions

- Colour / Finish: glossy, fine textured surface

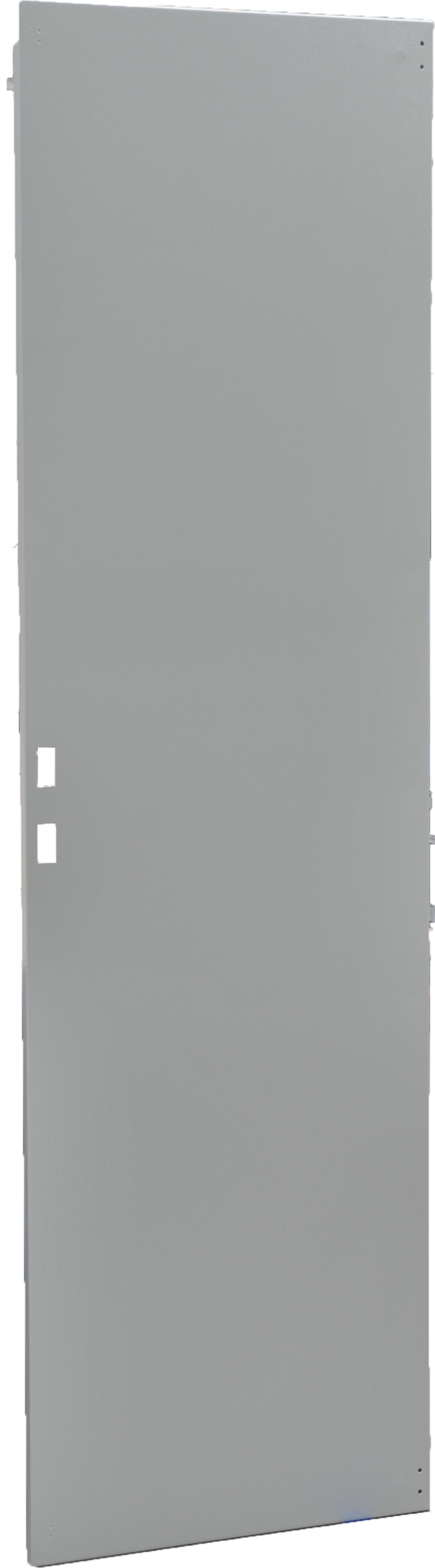

Single Parts

Doors

- Dimension (W x H x D): 200 x 1600 x 30 mm

- Construction: bend part with spot-welded structural components

- Colour / Finish: glossy with a fine textured surface

- Product surface finish: perchlorinated corrosion protection

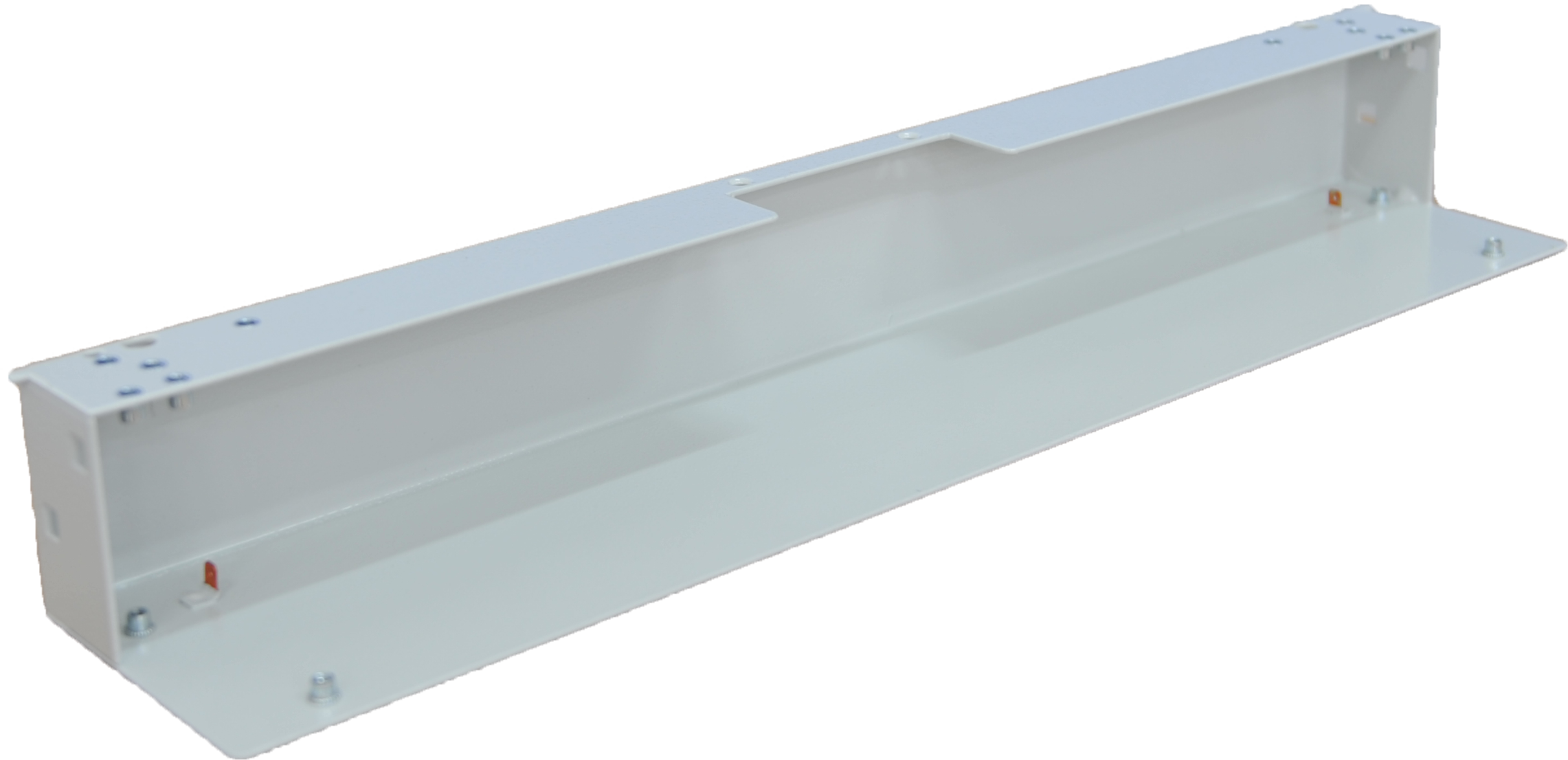

Single Parts

Shelfs

- Dimension (W x H x D): 380 x 400 x 400 mm

- Construction: bend part with spot-welded structural components

- Colour / Finish: glossy with a fine textured surface

- Product surface finish: perchlorinated corrosion protection

Single Parts

Welder’s outer casing / enclosure

- Dimension (W x H x D): 200 x 450 x 600 mm

- Construction: bend part with spot-welded structural components

- Colour / Finish: glossy with a fine textured surface

- Product surface finish: perchlorinated corrosion protection